Almost everyone who works with metal or wood knows what a stationery chuck is. This word might not mean anything to people who have never built anything or worked with wood before. To hold and turn a metal piece safely, a lathe needs a chuck that is stable. Because you have a lot of control over how you move the work, you can make clean cuts with this tool. We’ll talk about what a stationery chuck is, how it works, and why it’s important in the shop today. This article has all the information someone who is new to this tool needs to learn more.

Maximize precision with stationary chucks

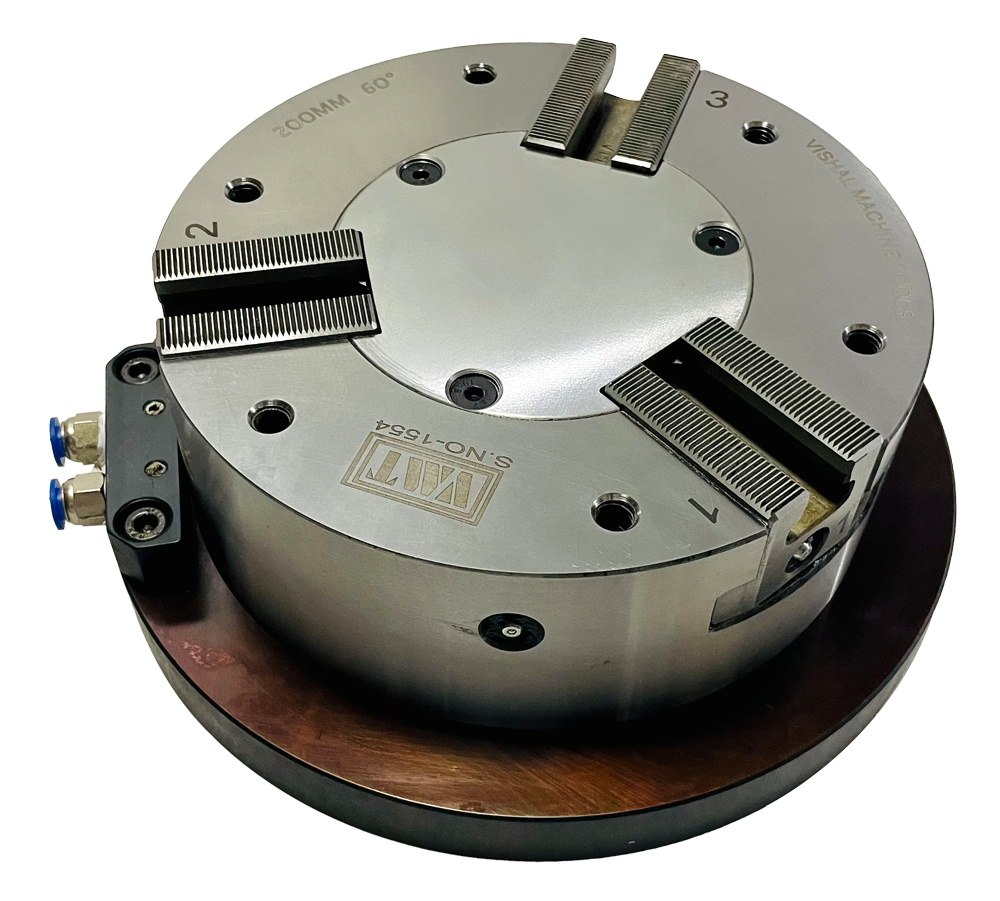

Make maximum precision in the machining routine possible by adding work holding devices to your process flow. Despite their importance, stationary chucks are often overlooked tools that are used in different machining processes to securely hold workpieces, as this enables the accurate and stable machining of the workpieces by cutting, drilling, or milling operations.

Benefits of Stationary Chuck

- Increased accuracy

- Secure tool grip

- Reduced vibration

- Versatile use

Securely hold workpieces in place

It might be best and easiest to use a set holding chuck to hold the pieces tightly in place. Simply put, a chuck’s main job is to hold the part tightly so it doesn’t move or slip around while the construction is going on. There is a much smaller chance of damaging both the subject and the machine itself, which makes the machine very accurate. These give a strong grip that can stand up to the forces used for cutting, drilling, or turning.

Improve machining accuracy and efficiency

Selecting the stationary chuck and making sure it is aligned and set up correctly is the preliminary step. This is achieved by placing the workpiece in the chuck, aligning it perpendicularly with the machining axis, and clamping the jaws firmly. In the case of misalignment, loosening or tightening, it can cause inaccuracies and make the system less efficient.

With a clearer idea of what a chuck is and how it performs, you can make the right decision in choosing the right chuck for your milling requirements. Recollect things like jaw size, material, and gripping force while picking a stationary chuck. Incorporating the right stationary chuck will definitely enhance the accuracy and economy of your machining processes, leading to an improvement in the quality of the final product.

Website: https://www.vishalmachinetools.com/