Are your parts slipping during machining? The right chuck can make or break your production quality. A hydraulic chuck system might be what you need, but let’s find out if it matches your shop’s needs.

The Basic Differences That Matter

Power chucks run on electricity and give you quick setup changes. They’re like the reliable pickup truck of the machining world.

Think about it this way: You can plug them in anywhere and get to work. Plus, they cost less upfront.

Why Power Chucks Make Sense

Power chucks shine when you need:

- Quick part changes

- Lower startup costs

- Simple maintenance routines

- Flexible power options

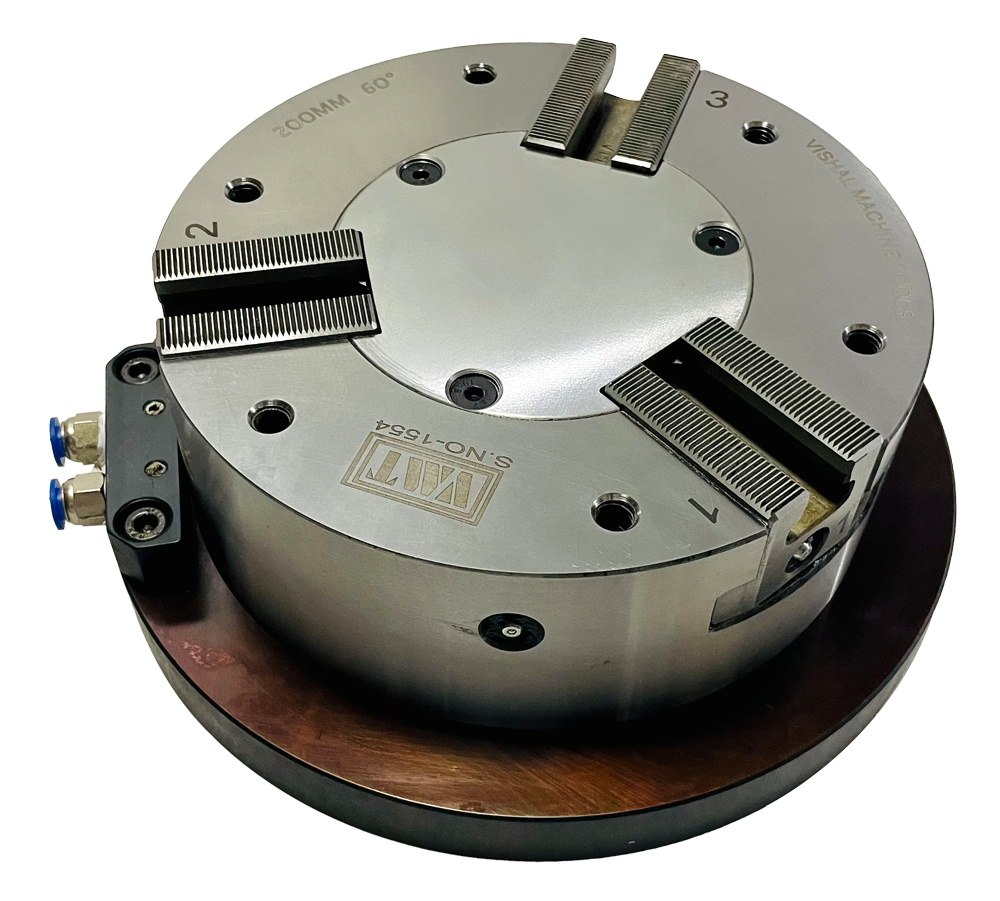

When a Hydraulic Chuck Wins

For precision work, nothing beats hydraulic systems. They give you:

- Better grip strength

- Less vibration during cuts

- Consistent pressure all day long

- Smoother operation at high speeds

Real Talk About Costs

Let’s get down to numbers. Power chucks usually cost $2,000 to $5,000.

Hydraulic systems? They start at $4,000 and go up from there.

But here’s the thing: Think about what you’ll save on scrap parts and rework.

Speed vs Precision Tradeoffs

Power chucks let you swap parts faster. Great for high-volume shops.

Hydraulic chucks take longer to set up, but nail those tight tolerances.

Setup Tips That Save Time

Want faster setups? Try these tricks:

- Mark your common diameter settings

- Keep pressure gauges in clear view

- Store common tools nearby

- Clean chuck jaws daily

Maintenance Matters

Keep your chuck running smooth:

- Check seals monthly

- Clean after each shift

- Watch for pressure drops

- Listen for unusual sounds

The Truth About Long Term Value

Think five years ahead. Which system matches your growth plans?

Have you considered:

- Your typical part sizes?

- Required tolerances?

- Production volume goals?

- Available shop space?

Making Your Choice

Both systems work great. Your pick depends on your needs.

Need speed and simplicity? Power chucks fit the bill.

Want precision and consistency? Go hydraulic.

What matters most is matching the chuck to your actual work, not what others say you should buy.

Have you used both types? What’s been your experience?

Remember: The best choice is the one that helps your shop deliver quality parts on time, every time.