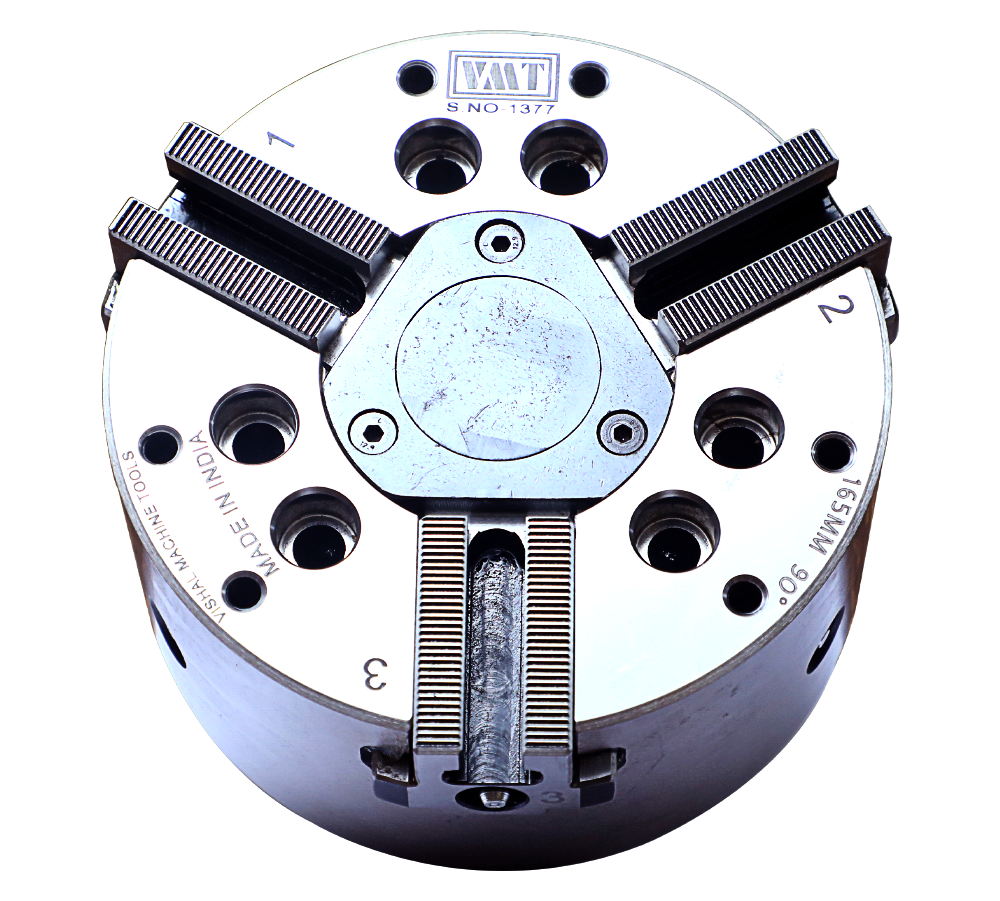

1. Identifying the Appropriate chuck for the Job

When choosing the suitable chuck for the job, it is essential to know the specific application and function required. The chuck must be able to withstand the intended load, as well as be able to grip the workpiece efficiently. Additionally, it is essential to consider the type of spindle, material, and size of the chuck necessary for the job. Various compensation chucks are available, from self-contained scroll chucks to lever-operated chucks, depending on the application. One can quickly identify the ideal chuck for the job by determining the desired use.

2. Preparing the Chuck for Use

Preparing your chuck for use is a simple task that involves a few steps:

- You need to identify the type of chuck you have and ensure it is compatible with your machine.

- Attach the chuck to the machine’s spindle and tighten the mounting screws.

- Adjust the chuck’s jaws to the desired opening size.

- Insert the material into the chuck and secure it by tightening its jaws.

- Use the appropriate wrench to turn the spindle’s drawbar to ensure the fabric is properly.

These steps will ensure your materials are clamped securely, and your machine is safe to use. Proper preparation of your chuck is essential for a successful tailoring experience.

3. Adjusting the Chuck for Optimal Performance

The optimal Performance of your compensation chuck relies on proper adjustment and maintenance. When adjusting the chuck, you should ensure it is properly mounted and secure. Once the chuck is mounted, you will want to check that the jaws are snugly closed and that the screws are correctly tightened. Next, you will want to ensure that the locking nut is adjusted correctly. You can change the nut by hand or use a torque wrench. Finally, checking the jaws and screws is essential to ensure that they are properly aligned and that the tension is set correctly. With the proper adjustment, your chuck will be able to deliver the highest levels of Performance and accuracy. Adequate maintenance and adjustment of your chuck will also help to ensure its longevity and optimal Performance.

4. Maintaining the Chuck for Extended Use

Maintaining the Chuck for Extended Use is essential for tailors looking for the best possible experience. Regular cleaning and lubrication of the chuck can significantly extend its lifetime. By ensuring that any dust or debris is regularly removed from the chuck, the user can prevent wear and tear from forming. Additionally, it is essential to lubricate the chuck regularly to prevent rust and corrosion from occurring.

Following these steps will ensure that you are able to get the chuck that is perfectly customised for your needs.

Website: https://vishalmachinetools.com/