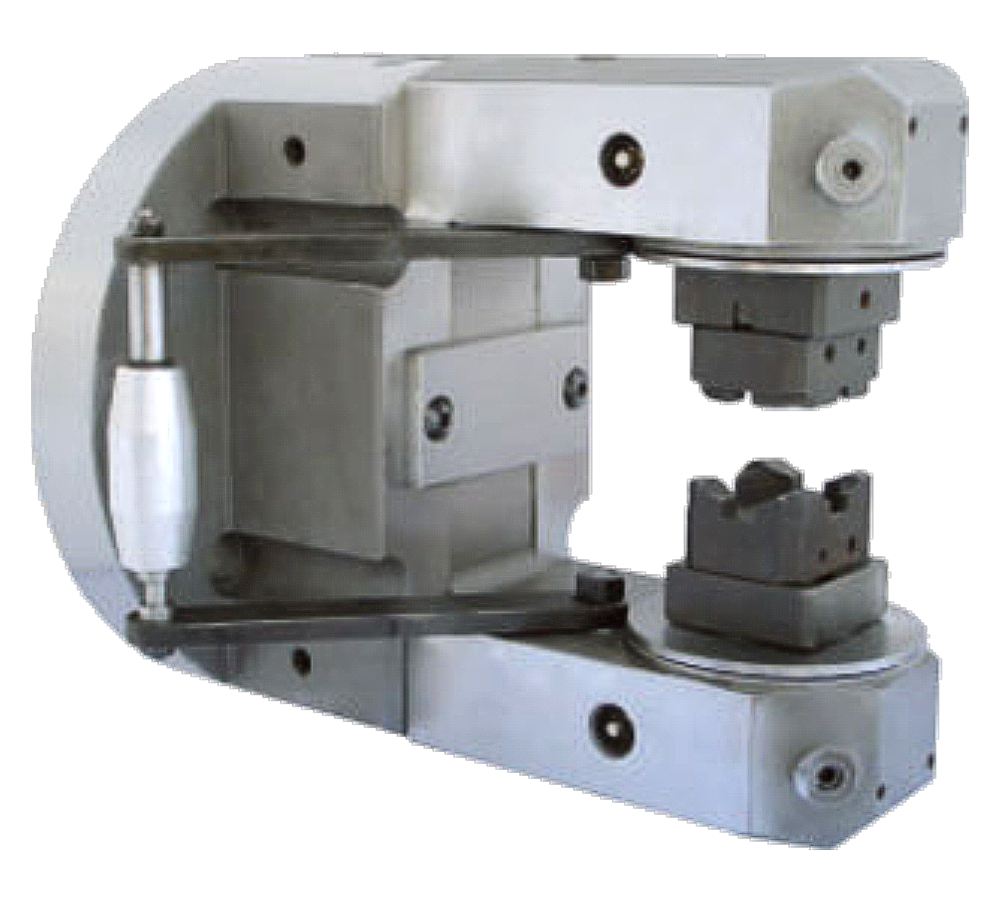

Manual indexing chucks are devices that hold and rotate workpieces in machining operations. They consist of a base with jaws that clamp onto the workpiece and an index plate that allows the operator to adjust the angle of rotation. Manual indexing chucks are widely used in various industries, such as aerospace, automotive, medical, and metalworking. But what are the advantages of using manual indexing chucks over other types of chucks? Here are some of the benefits:

Precision and accuracy: Manual indexing chucks allow the workpiece to be placed and turned with high precision and accuracy. The index plate has a series of holes or slots that correspond to different angles of rotation, like 15°, 30°, 45°, etc. With a pin or a lever, the operator can lock the index plate at any angle he or she wants. This ensures that the workpiece is aligned and oriented correctly for the machining operation. Manual indexing chucks also have a high clamping force and stability, which prevent the workpiece from slipping or moving during machining.

Versatility and flexibility: Manual indexing chucks can handle a wide range of workpieces with different shapes, sizes, and materials. They can accommodate round, square, hexagonal, or irregular-shaped workpieces with ease. They can also be used for various machining operations, such as drilling, milling, turning, boring, tapping, etc. Manual indexing chucks can be mounted on different machines, such as lathes, milling machines, drill presses, etc. They can also be combined with other accessories, such as faceplates, collars, centres, etc., to increase their functionality and adaptability.

Simplicity and cost-effectiveness: Manual indexing chucks are simple and easy to use. They do not require any power source or complex control system to operate. The operator can manually adjust the angle of rotation and clamp the workpiece with minimal effort and time. Manual indexing chucks are also relatively cheaper than other types of chucks, such as hydraulic or pneumatic ones. They have fewer parts and components that can wear out or break down over time. They also require less maintenance and repair.

Manual indexing chucks are good for machining jobs that need precision, accuracy, versatility, flexibility, simplicity, and cost-effectiveness. They are suitable for various industries and applications that involve rotating and positioning workpieces. Manual indexing chucks can improve the quality and efficiency of machining processes and products.

Website: https://www.vishalmachinetools.com/