Essential machining equipment, collet chucks hold components firmly during turning, milling, and grinding. Their design guarantees production precision, efficiency, and safety.

Collet chucks are indispensable in the world of machining. Their strong grip on workpieces allows consistency and accuracy. We will explore collet chucks’ use, features, and advantages in this essay.

What Are Collet Chucks?

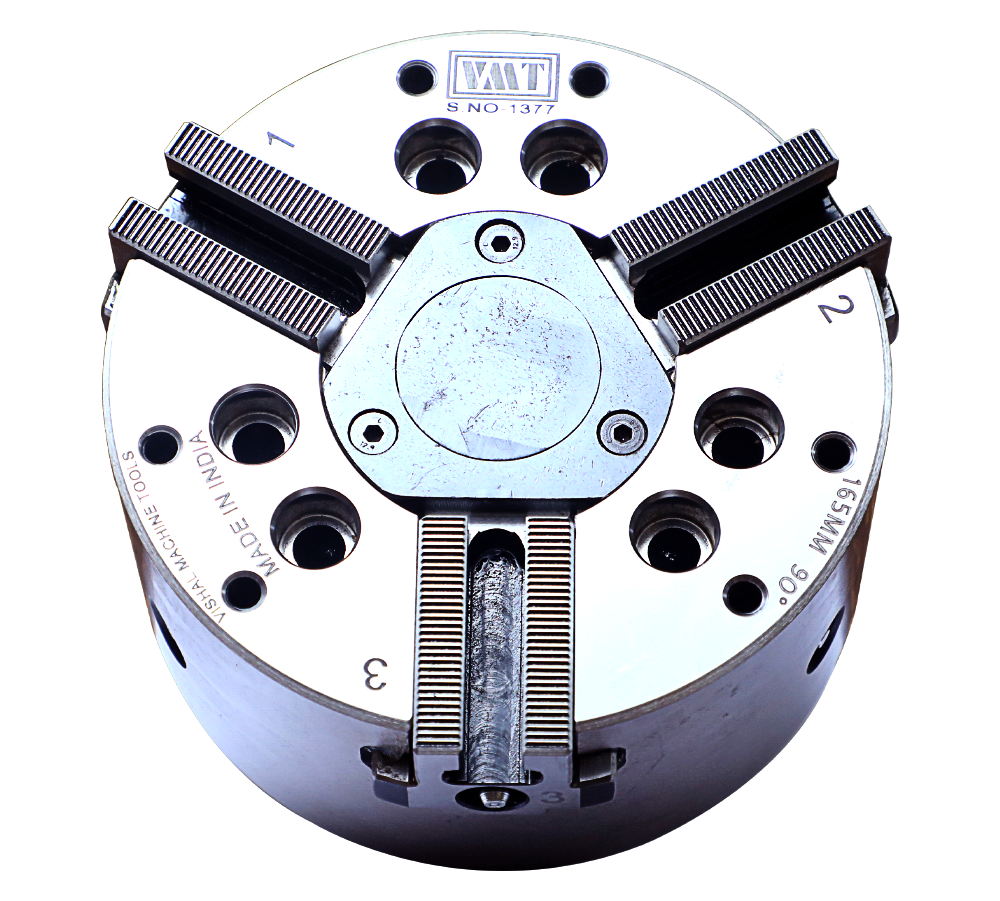

In machining, a collet chuck is a device for gripping workpieces. It compresses around the workpiece when tightened with a collet—a cylindrical sleeve with slits. This guarantees a strong, concentric hold that keeps the component constant throughout the machining process.

Because of their great gripping strength and ability to preserve great precision, collet chucks are increasingly used. By lowering vibrations and avoiding slippage, they guarantee exact results in many different uses.

How Do We Use Collet Chucks?

Collet chucks are versatile and find applications in many machining tasks. Let’s explore some of their primary uses.

1. Turning

In turn, a lathe spins the workpiece while a cutting tool shapes it. Collet chucks excel in holding cylindrical parts, ensuring they remain steady during rotation.

- Shafts: Their long and slender nature makes shafts prone to deflection. Collet chucks ensure a tight grip, minimizing vibration and maintaining precision.

- Cylinders: For components like bolts, pins, or other cylindrical objects, collet chucks provide the accuracy required for perfect symmetry.

2. Milling

Milling involves removing material to shape or finish a part. Collet chucks are ideal for securing small or irregularly shaped workpieces. Their precision grip ensures stability, leading to clean and accurate cuts.

3. Drilling and Boring

Drilling creates holes while boring enlarges them. Collet chucks keep the workpiece perfectly aligned, ensuring holes are centered and consistent in size. This is particularly critical for parts that demand exact tolerances.

4. Grinding

Grinding smooths surfaces and brings parts to their final dimensions. Collet chucks provide the steadiness required for even finishes, ensuring components fit together seamlessly.

Why Are Collet Chucks Important?

Collet chucks are indispensable for precision manufacturing due to their numerous advantages:

- Accuracy: By minimizing runout, its concentric clamping guarantees that machined items are accurate.

- Versatility: Their adaptability for a range of forms and sizes qualifies them for different uses.

- Efficiency: Collet chucks, which are quick and simple to set up, save downtime and increase output.

- Safety: They stop unexpected movements of the workpiece that might endanger operators by strong gripping.

Types of Collet Chucks

Collet chucks come in various designs to suit different needs:

- Standard Collet Chuck

The most common type is ideal for general-purpose machining tasks. - Dead-Length Collet Chuck

These maintain a fixed axial position, ensuring consistent length for parts during high-precision operations. - Sealed Collet Chuck

Designed to protect against debris, these are excellent for environments with heavy coolant or fine particles. - Quick-Change Collet Chuck

Engineered for rapid tool changes, these minimize setup time and are perfect for high-volume production.

Conclusion

Precision manufacturing depends much on collet chucks. Workpiece firmly grasping improves precision, guarantees safety, and increases efficiency throughout turning, milling, drilling, and grinding operations.

From building sensitive instruments to manufacturing car parts, collet chucks enable machinists to reach unmatched dependability and accuracy. Investing in premium collet chutes is very essential if you want to optimize your machining processes.