In the manufacturing and metalworking industries, precision and safety are inseparably intertwined. The main contributor to the secure holding of workpieces in both of the cases is the chuck, a vital tool that is used in lathes. The purpose of this blog is to show you the necessary maintenance procedures for power chucks in order to make your operations both safe and effective.

Routine Inspection is Key

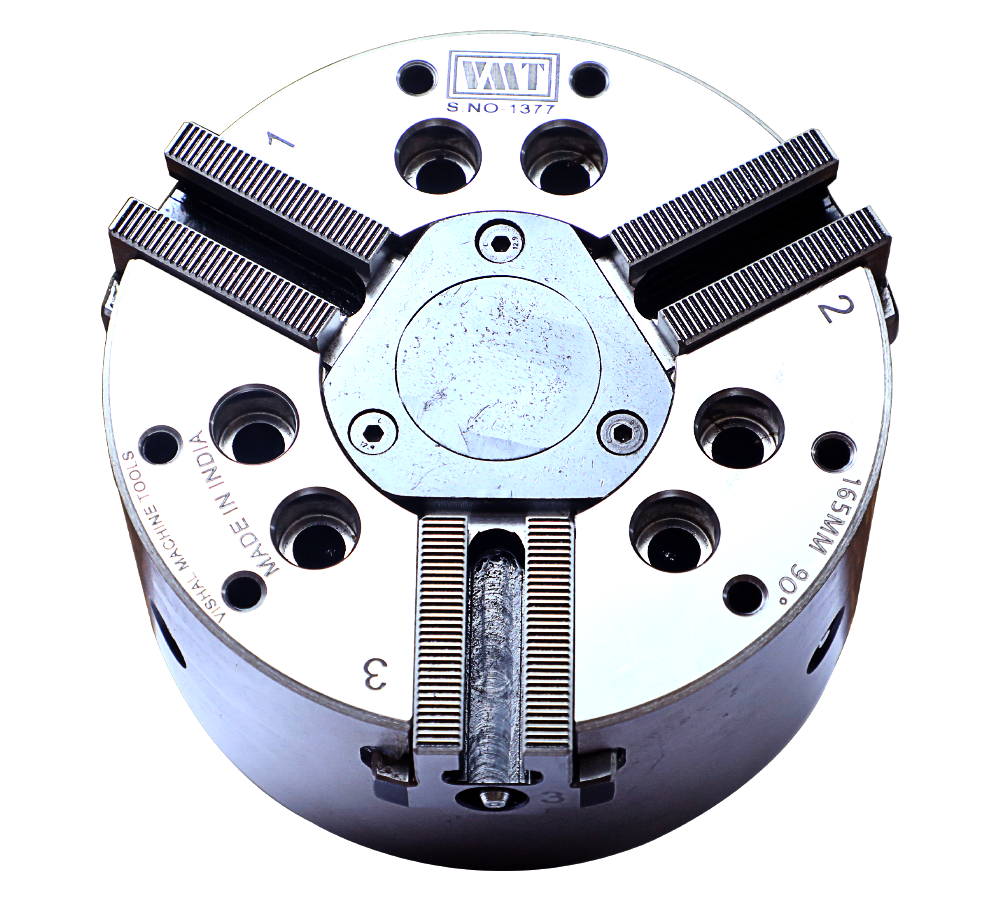

The first phase of running the power chuck is to regularly inspect it. Inspections on a regular basis are aimed at detecting deterioration or any risk that may develop into more severe problems. Seek for corrosion, cracks, and any other damages. Check that the chuck functions without any unusual resistance or sounds that might mean the inside parts are not working properly.

Lubrication: The Lifeline of Your Power Chuck

Lubrication is the precondition for the long life and flawless operation of power chucks. It minimises the friction between moving parts and thus prevents the premature wear and tear of the chuck, which extends the longevity of the chuck. Use the manufacturer-recommended lubricant and adhere to the guidelines for its application. This alone can solve the issues that may arise and let the power chuck operate to its maximum capacity.

Cleaning: A Non-Negotiable Routine

Chips and the debris of metal could collect in and around the chuck of the power chuck, thus destroying the chuck or contributing to its inaccuracy. Clearly, cleaning should be done at regular intervals in order to eliminate these contaminants. Use an ultra-soft brush or compressed air to micro clean the chuck after each use. Keeping the chuck clean maximises the service life of your equipment and also preserves the accuracy of the work.

Professional Maintenance and Repairs

Sometimes simple maintenance tasks can be done without professional consultation, but some complex situations require special assistance. If you ever observe major damage to the tool or a faulty power chuck despite regular cleaning and maintenance, it is time to get professional repairs.

Conclusion

Your power chuck is not just about extending its lifetime; it’s about securing the coherence and efficacy of your operations. By applying these key elements of maintenance, you guarantee that the power chuck remains a robust and secure tool in your manufacturing equipment.