Collet Chuck Manufacturing Company

Collet Chuck

VMT, Collet Chuck is available in three size 25, 42 and 60. These Chuck are interchangeable with power chuck. Collet chuck type has spring collect type collect chuck with great rigidity and infallible. Collet Chuck increase efficiency and productivity always high performance, cost effective and great stability. We also provide customized solution if you need a customized Collet chuck.

VMT, Collet Chuck applies clamping force all the round the diameter of the part instead of just selected contact area. This result in high concentricity.

A collet chuck is a type of clamping device used in machining and manufacturing to hold workpieces or tools securely in place. It consists of a cylindrical sleeve (the collet) that can be tightened around a tool or workpiece to ensure a firm grip.

The main features and benefits of a collet chuck include:

- Precision: Collet chucks are known for their high precision and can hold tools very accurately, making them ideal for CNC machining.

- Ease of Use: They allow for quick tool changes without the need for complex setups.

- Strength: They provide a strong grip, which is essential for high-speed machining operations.

- Versatility: Collets come in various sizes and shapes to accommodate different tool diameters and types.

- Uniform contact: Unlike traditional vises, collets provide uniform contact along the tool's shank, improving stability.

Collet chucks are commonly used in lathes, milling machines, and other types of manufacturing equipment. If you have specific questions about types of collet chucks, their applications, or how to use them, feel free to ask!

Get A Quote

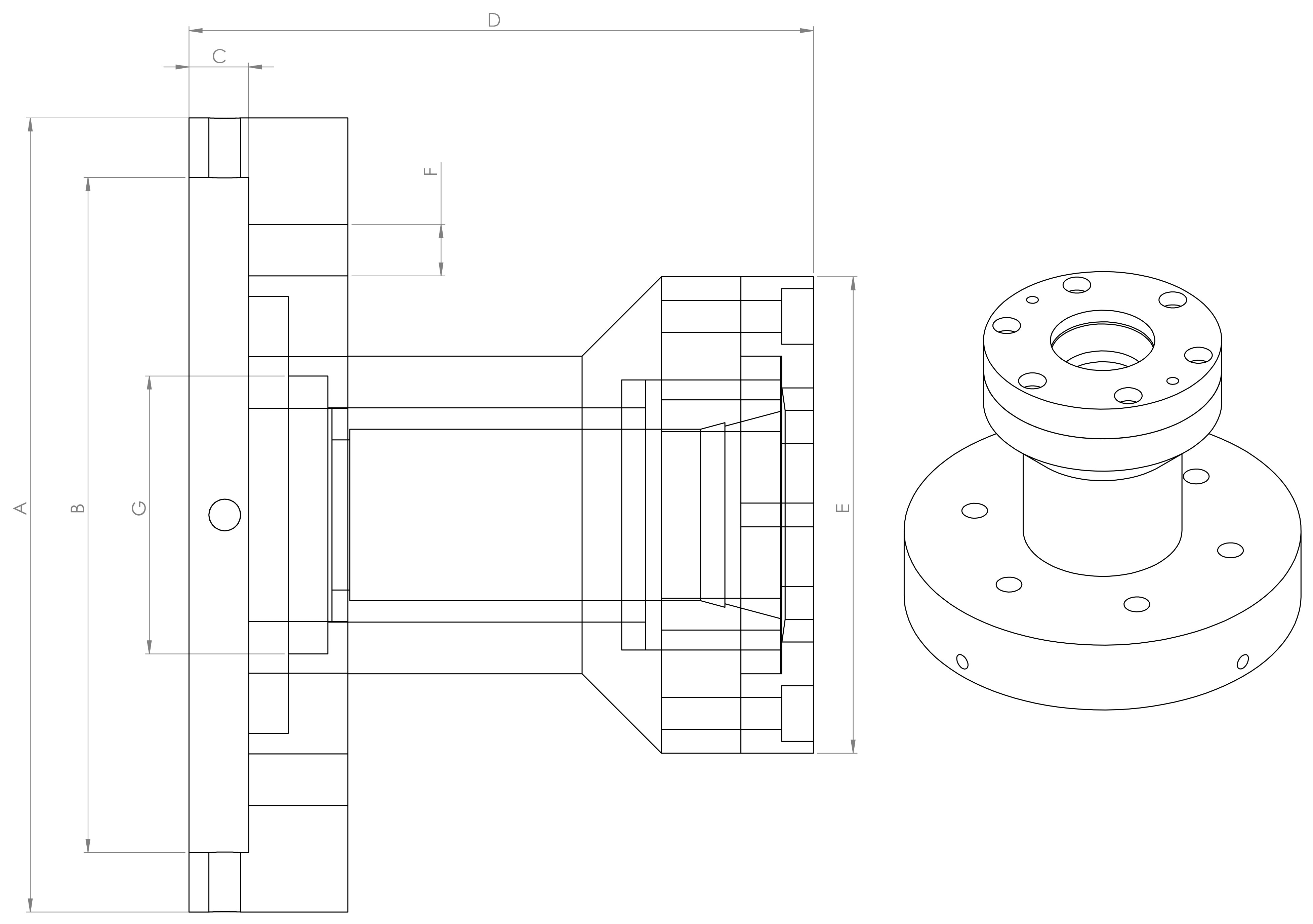

Product Drawing

| Model | A | B | C | D | E | F | G | PCD |

|---|---|---|---|---|---|---|---|---|

| 135 | 135 | 110 | 10 | 115 | 80 | M10X6 | 44 | 82.6 |

| 165 | 170 | 140 | 10 | 138 | 120 | M10X6 | 70 | 104.8 |

| 200 | 200 | 170 | 10 | 149 | 120 | M12X6 | 70 | 133.4 |

| Specification | Clamping Range | Sleeve Storke | Max. Force | Accuracy | RPM |

|---|---|---|---|---|---|

| 135 | 2-25 mm | 5 mm | 15 bar | 0.01 | 6000 |

| 165 | 2-25 mm 2-42 mm |

5 mm 5 mm |

15 bar | 0.01 | 5000 6000 |

| 200 | 2-25 mm 2-42 mm |

5 mm 5 mm |

15 bar | 0.01 | 4000 4000 |